Point repair

Riparazioni localizzate | Point repair

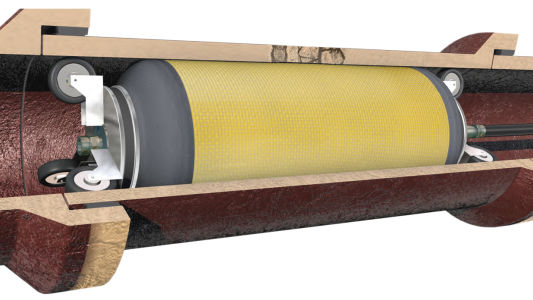

Un pallone di nuova generazione, avvolto in un tappeto di fibra di vetro imbevuto di resina, viene spinto con mezzi pneumatici, oppure tirato con una corda fino al punto danneggiato del tubo esistente le cui coordinate sono state precedentemente prodotte con un’ispezione televisiva. Una volta raggiunta la posizione, il pallone viene gonfiato con aria compressa. In questo modo, il pallone si espande fin contro la parete del tubo, schiacciando contro di essa le fibre di vetro impregnate di resina.

L’eccesso di resina fuoriesce e va a riempire le zone danneggiate della parete del tubo, dove restano in modo permanente. La fibra di vetro impregnata di resina viene poi catalizzata a temperatura ambiente, secondo le istruzioni del produttore di resina. I tempi di polimerizzazione della resina possono variare a seconda delle condizioni all’interno del tubo.

Una volta completata la polimerizzazione della resina, il pallone viene sgonfiato e rimosso dal condotto. A questo punto il tappeto di fibra di vetro ricopre tutta la zona interessata senza alcun intralcio al flusso. Il tubo riabilitato in questo modo è una struttura integra che risponde pienamente alle caratteristiche idrauliche richieste.

Riparazione di laterali

Per i laterali si utilizzano palloni LCR anch’essi avvolti da resina e spinti da una serie di cilindri pneumatici o su un carrello, oppure tirato da una corda fino al punto da riparare, le cui coordinate sono state precedentemente prodotte con un’ispezione televisiva. La particolarità di questi palloni è che sono dotati di un’asta telescopica regolabile in base all’angolo di raccordo del canale laterale e dotata di un profilo a cappello rovesciato e impregnato di resina.

L’asta, essendo telescopica, si trova all’interno del pallone fino al punto della diramazione dove viene sfilata e invertita al suo interno ad aria compressa. Una volta raggiunto il punto da riparare, l’aria compressa viene gonfiata all’interno del pallone. L’asta che si trova all’interno viene spinta fuori in corrispondenza della diramazione laterale del tubo e spinta contro il bordo del punto di raccordo con una forza tale da garantirne la tenuta.

La resina in eccesso penetra nelle cavità del tratto danneggiato formando un unico corpo con le fibre di vetro del cappello e le pareti del tubo esistente. Il profilo del cappello è fatto appositamente per garantire la sigillatura dello spazio tra cappello e laterale, mentre il pallone LCR si presenta come una manichetta localizzata.

Sia nel caso del pallone, sia in quello del cappello, la resina viene polimerizzata a temperatura ambiente in base alle istruzioni del suo produttore. I tempi di polimerizzazione della resina possono variare a seconda delle condizioni all’interno del tubo. Una volta catalizzata la resina, il pallone viene sgonfiato, l’asta telescopica ritirata al suo interno e il tutto rimosso dalla tubazione.